As seen in Raconteur, ‘Supply Chain Resistance’ – The Sunday Times, 5th Sept 2021.

On the road to net-zero logistics

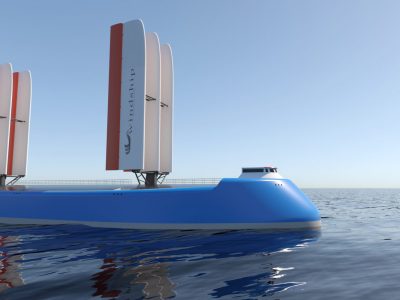

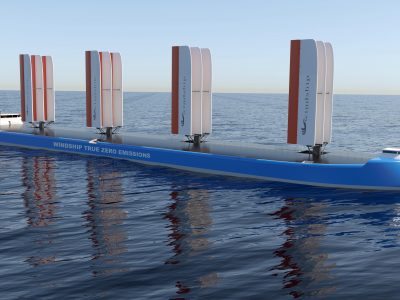

“When it comes to rethinking ship design, the ‘True Zero Emission concept from British company Windship Technology promises more disruptive innovation. Dubbed ‘the Tesla of the seas’, its triple-wing rigs harness the power of the wind, with the look of a 21st-century clean-tech clipper.” Jim McClelland.

Windship Technology and Calix Limited execute joint development agreement targeting zero-emissions shipping

Windship Technology shortlisted for The Motorship Award

Graham Harvey appointed as Chief Executive of Windship Technology

Windship Technology confirms attendance at the Society of Maritime Industries Conference 2021

Pioneering British company, Windship Technology powers first True Zero Emission ship design with high performance rig technology

Leading expert knowledge and CFD analysis

Windship and DNV unveil ‘first true zero-emissions’ design

UK company claims new wind-powered system is the "Tesla of the seas". Windship Technology has revealed what it claims is the world's first truly zero-emissions ship system. The UK company has brought Norwegian classification society DNV on board to help develop a wind-powered design it refers to as the "Tesla of the seas".... "Per Marius Berrefjord, senior vice president at DNV, called the Windship team "experienced professionals". He said the project aims to help bring the entire shipping industry to "true zero" in terms of emissions. "Windship is supplying information in a fully transparent manner, and DNV will ensure a thorough verification process. We are looking forward to dive deeper into the very interesting technology presented by Windship," the DNV executive added. Windship is now looking to seal commercial partnerships with major shipowners, operators and investors, the UK company said. The Windship board includes former Concordia Maritime chief executive Lars Carlsson. The ex-tanker executive said: "The industry cannot sit back any longer. The clock is ticking and regulation will force a new approach for an industry that is traditionally hesitant to change." He added shipping is not fit for purpose for the future. Carlsson has been advocating wind power for a number of years. He said in 2019 that owners should be using all known fuel-saving methods, including wind propulsion, lower speeds, design and operational optimisation and biofuels derived from waste. And he called for new vessels to be built with anti-corrosion coated steel to give them a longer trading life of 50 years, a global fossil-fuel tax to encourage sustainable investment and the creation of a carbon exchange trading market.Read the full article from Tradewinds > Tradewinds subscribers, click here to find out more from Tradewinds >

The ‘Tesla of the Seas’ – pioneering British company, Windship Technology unveils first True Zero Emission ship design

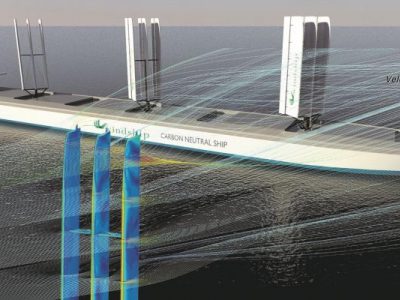

Use of fluid mechanics improves the efficiency of wind-assisted ships

UK-based Cape Horn Engineering has reported a two-digit percentage improvement in the aerodynamic performance of a vessel’s solid wing assembly via the use of Computational Fluid Dynamic (CFD) programme. The use of Wind Propulsion Technology (WPT) such as rigid wings, sails, kites, Magnus rotors on some vessels like bulk carriers and tankers have the potential of fuel savings and emission reductions around 10-30%.

Cape Horn Engineering said it is supporting one of its clients, Windship Technology, on a solid wing power concept that is being developed by a consortium of key players in the global shipping industry.

“We are extremely proud to be part of the team led by Windship Technology for this exciting project, running a CFD programme to further improve the design of the solid wings,” said Rodrigo Azcueta, managing director of Cape Horn Engineering.

“One of the key focuses of our project is to provide a clearer, unbiased and more detailed analysis of the new technologies available. The analytical evidence provided will give businesses a clearer understanding of the potential savings that can be realised with the implementation of the green propulsion systems. Without significant mitigating action it is projected that the global shipping industry could account for almost a fifth of carbon emissions by 2050,” Azcueta said.

Read the full Seatrade Maritime News article: here.