Decarbonising Superyachts using wind power

Written by David Barrow, Windship Technology Director

Wind power is taking off throughout the commercial shipping industry with Owners and charterers realising that the emissions controls are getting tougher, and are going to continue to do so until 2050.

Superyachts have not been hindered much yet, but it is only a matter of time before stricter regulations come in.

There have been attempts at using wind power in bigger yachts with some success, but there does not seem to be appetite yet for bigger power boats to really look at designs to incorporate fuel saving measures such as wind power.

Having watch a circa 230 foot superyacht refuel with 250,000 litres of diesel I worked out that would be roughly 700 tons of Co2 created by that one tank of fuel.

I am sure we were all amazed, at the recent America's Cup, to see the 75 foot yachts reaching speeds of between 50 to 60 knots purely due to the speed of the wind and even in 8 knots of windspeed they were able to sail at 32 knots, 4 times the speed of the wind. These were extraordinary yachts sailing on hydrofoils, not luxury superyachts. However it does give some idea of the great power these wing systems can provide and there are ways of delivering this to the superyacht market in future. To give you an idea the ship below with 3 35 metre masts with 3 wings on each mast, in 25 knots of wind across the beam of the ship, the wind is providing the same power as the ships engine.

In future hulls will need to be more easily driven, more dynamic, with better stability.

There must be a middle way between the current superyacht powerboats, and superyacht sailboats, a hybrid form that is acceptable to the superyacht owner and the drive for greener superyachts in general.

Fuel additives are also appearing that are green in the way they are produced and provide added benefits, such as cleaner burning fuel reducing soot, smoke, and other particulate matter, eliminating diesel bug, increasing fuel efficiency, making the engine run more efficiently, up to 6%. So our big superyacht would have an additional benefit of 15,000 litres of fuel to use just by adding a product like www.SulNOXgroup.com.

A time to think ahead and embrace what the future will certainly be rather than stay with current thinking and react only as legislation slowly turns the screw.

Photo by redcharlie on Unsplash

IMO MEPC 80: Shipping to reach net-zero GHG Emissions by 2050

The 80th session of the IMO’s Marine Environment Protection Committee (MEPC 80) adopted a revised GHG (Greenhouse Gas) Strategy. The revised strategy aims to significantly curb GHG emissions from international shipping. The new targets include a 20% reduction in emissions by 2030, a 70% reduction by 2040 (compared to 2008 levels), and the ultimate goal of achieving net-zero emissions by 2050. New regulations are expected to enter into force around mid-2027.

The 2023 Strategy also has a new level of ambition, that originates from work originally done by UMAS and the High Level Climate Champions and Global Maritime Forum - namely that uptake of zero or near-zero GHG emissions technologies, fuels and/or energy sources to represent at least 5%, striving for 10% of the energy used by shipping by 2030. This is a key enabler of early investment into the long - run solutions that can ensure this decade will see emergence and increasing use of zero emissions technologies and supply chains, ready for their rapid scaling from 2030.

Windship Technology has the zero emissions solution for commercial shipping.

Fusing the expertise of world-leading ship designers and shipping industry veterans, Windship Technology Ltd has a fully patented triple rig wing design and a whole-ship solution harnessing wind technology, carbon capture, solar energy, renewable power, weather routing, hull design and highly innovative engine design.

Windship Technology is essential to the global transportation revolution. The shipping sector is ready for change. Windship Technology has the solution to make it happen. Contact us on info@windshiptechnology.com for further information.

Source: https://www.dnv.com/news/imo-mepc-80-shipping-to-reach-net-zero-ghg-emissions-by-2050-245376

International Women’s Day: Spotlight on Hattie Rogers

On International Women’s Day, Windship Technology is proud to put the spotlight on Hattie Rogers.

From a very young age, Hattie started sailing on Contessa yachts built by her grandfather and went on to study Ship Science and Engineering at the University of Southampton, where she graduated with a first in her Masters, last summer. Hattie is the daughter of Simon Rogers, our Technical Director, and has worked behind the scenes with Windship Technology during her degree and beyond.

Hattie said, “It fills me with pride to be a young woman and trail blazing a new pathway in professional sailing for women and youth, as well as being a recently qualified Engineer. It is great that both industries are now fully embracing women.”

Hattie was involved in the Windship Technology testing (pictured) that was completed at the RJ Mitchell Wind Tunnel at the University of Southampton, during her degree. Hattie set up the model, conducted the testing and collected data. The testing involved looking at the predictions from the Computational Fluid Dynamics (CFD) analysis by Cape Horn Engineering, and DNV (who have given Windship Technology an AIP), testing a series of attack angles and flap angles at 20m/s, smoke visualisation at 3m/s and UV light testing tell-tales.

Hattie is fascinated by engineering principles and their applications, particularly in the fields of sustainability and decarbonisation of shipping and optimisation of sailing performance. Combine this with her love of water and the Ship Science Degree proved the ideal choice.

Hattie said, “Windship Technology has the solution to eliminate CO2 emissions from commercial shipping. If the shipping industry remains unchanged, it is predicted that it will rise from the current figure of 3% to 10% of global CO2emissions by 2050 - when I will be 50. There is no doubt that this demonstrates that the Windship Technology project will significantly help to combat climate change for my generation and beyond.”

A spokesperson on behalf of the Windship Technology Board said, “We are so proud of Hattie and all she has achieved. One of the reasons we care so passionately about Windship Technology is that we believe our solution for the shipping industry will help fight climate change which will have a direct positive effect on the future of our families and yours.”

Described as "the face of the foiling generation" by esteemed sailing journalist Magnus Wheatley, Hattie won the SailGP WASZP INSPIRE Grand Final in San Francisco last year and is an integral part of the Athena Pathway Programme* in the ETF26 Series**. This programme is led by the World’s most decorated Olympic sailors - Hannah Mills and Sir Ben Ainslie and seeks to select the British Youth and Women’s America’s Cup teams for Barcelona 2024. Hattie is targeting both teams as one of the two helms.

In February 2023, Hattie (22) became the youngest recipient of the prestigious YJA Yachtsman of the Year. The accolade, considered the most prestigious in British boating, was presented at the RYA Dinghy and Watersports Show. Previous winners include Sir Ben Ainslie, Dee Caffari, Sir Robin Knox-Johnston and Dame Ellen MacArthur. Hattie said the award was particularly special because it was previously won by her grandfather Jeremy Rogers in 1974, who sadly passed away in 2022.

Hattie has been sailing full-time since graduating in 2022 and is currently winter training in Palma. She said: “My main focus now is securing a helming position for the British Youth and Women’s America’s Cup teams for 2024 in Barcelona.”

We wish Hattie every success and the Windship Technology Board are proud to be part of her journey.

____________________________________

* The Athena Pathway, led by Hannah Mills, is a new pathway for female and youth athletes fast-tracking development in professional sailing, on and off the water, including into the America’s Cup and SailGP. The Pathway is founded with the pillars of ‘People, Planet and Purpose’ to encourage athletes to use their voice in the fight against climate change.

** The ETF26 foiling catamaran was born in 2017, designed by Guillaume Verdier, the naval architect who designed the winning boat Emirates Team New Zealand for the 34th edition of the America's Cup, as well as Jean-Pierre Dick, four times winner of the Jacques Vabre Race. The ETF26 is aimed for high-speed races, being able to reach 2.5 times the wind's speed, as well as adapt to different weather conditions, being able to foil between 8 - 20 knots. The boat weighs just 350 kilograms, and requires three to four sailors on-board. All boats raced in the league are one-design, with a fully carbon mast, and carbon-epoxy S-foils.

Clean Maritime Funding Secured by Windship Technology

Windship Technology has been awarded £4m as part of a consortium in the latest round of the UK’s Clean Maritime Demonstration Competition (CMDC). The project is a demonstration of a symbiotic wind propulsion and carbon capture system, aimed at making a zero-emissions shipping industry a reality.

This project will install a Windship Technology 36m tri-foiled rig on a 15,000DWT bulker alongside carbon capture technology being demonstrated by Leilac.

Graham Harvey, CEO of Windship Technology, said, “We are absolutely delighted with this funding for Windship Technology. Given the significant financial support announced today, the Department for Transport and Innovate UK believe Windship Technology can be a key driver in the clean shipping revolution, and we are proud to be playing our part in the decarbonisation of the shipping industry.”

Simon Rogers, Windship Technology Technical Director, commented, “The Windship Technology project has progressed significantly since we announced our DNV Approval in Principal. The next stage, thanks to this funding, will enable us to build a full-scale demonstration of our fully patented triple rig wing design working in conjunction with our partners carbon capture technology.”

The Windship Technology project is part of the Clean Maritime Demonstration Competition Round 3 (CMDC3), which was announced in September 2022, funded by the Department of Transport and delivered in partnership with Innovate UK. As part of the CMDC3, the Department allocated £60m to 19 flagship projects supported by 92 UK organisations to deliver real world demonstration R&D projects in clean maritime solutions. Projects will take place in multiple locations around the UK from as far north as the Shetland Isles and as far south as Cornwall.

Transport Secretary, Rt Hon Mark Harper MP, said:

“Our maritime sector imports 95% of goods into the UK and contributes £116 billion to our economy – more than both aviation and rail combined.

With growing the economy one of the government’s top priorities, we must continue our efforts to ensure the UK remains a pioneer in cutting-edge clean maritime solutions.

The funding we’re awarding today will help to do just that, bringing emission-free concepts to life and fuelling innovation.”

Innovate UK Executive Director for Net Zero, Mike Biddle, said:

"These 19 real world demonstration projects showcase the very best of UK clean maritime innovation and engineering, bringing a range of exciting technologies one step closer to commercial reality.

Accelerating clean maritime innovation is an important part of Innovate UK’s wider strategy and support to achieve Net Zero and unlock economic opportunities in the UK and globally."

CEO of the UK Chamber of Shipping, Sarah Treseder, said:

“Congratulations to all the successful bids, which cover a wide range of technologies and aspects of shipping.

The UK Chamber of Shipping is committed to net zero by 2050. This funding is an important milestone in ensuring we continue to work together to achieve this important target and will help us complete the journey from theory to reality for zero emission shipping.”

The CMDC3 is part of the UK Shipping Office for Reducing Emission’s (UK SHORE) flagship multi-year CMDC programme. In March 2022, the Department announced the biggest government investment ever in our UK commercial maritime sector, allocating £206m to UK SHORE, a new division within the Department for Transport focused on decarbonising the maritime sector. UK SHORE is delivering a suite of interventions throughout 2022-2025 aimed at accelerating the design, manufacture and operation of UK-made clean maritime technologies and unlocking an industry-led transition to Net Zero.

Contact Windship Technology on info@windshiptechnology.com.

Windship Technology publishes proprietary research highlighting the positive effect that its patented rig design can have in helping ship operators post the January 2023 EEXI environment legislation

Windship Technology tackles the problem of EEXI and EPL (Engine Power Limitation) with a long-term solution that extends the life of current and new-build ships

24th May 2022: The new regulatory framework (Energy Efficiency eXisting ship Index - EEXI) around CO2 emissions for existing shipping come into force in January 2023 and many ship owners are now considering how to meet these through either operational changes or technical alterations.

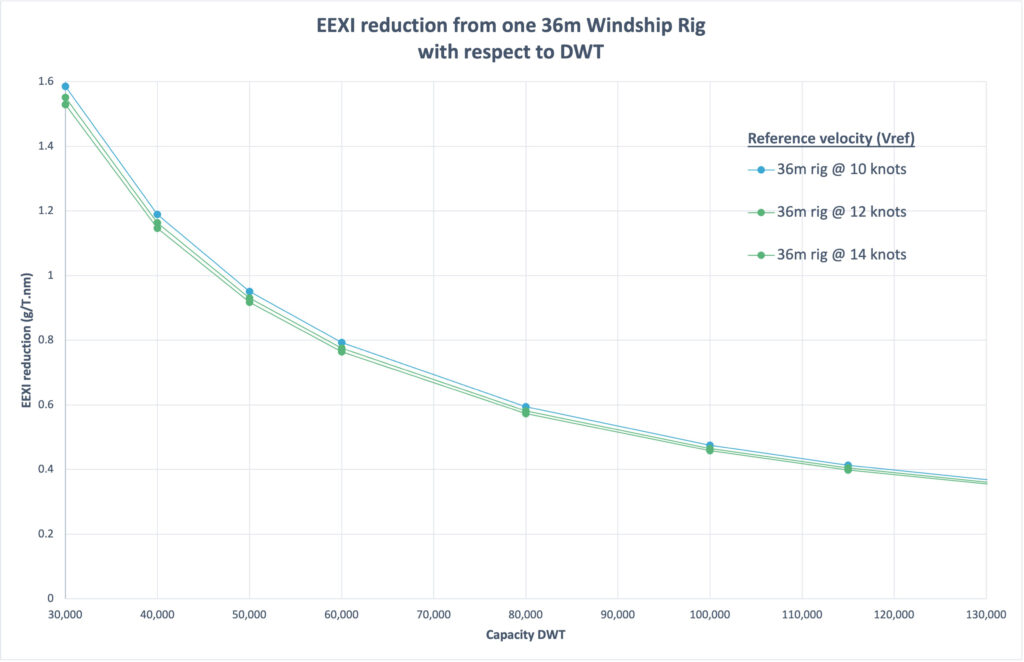

Windship Technology today publishes proprietary research that allows ship operators, owners and charterers the ability to easily see the positive, game-changing operational effect that installing just one 36m rig can have on their vessel going forward.

These regulations seek to measure the efficiency of ships through the amount of CO2 emitted per tonne per mile of freight carried in a year. Ships will be rated annually, from A, the highest performing, to E the lowest and the results will be recorded in the Ship Energy Efficiency Management Plan (SEEMP). Ships rated D for three consecutive years or E for a single year need to develop an approved corrective action plan as part of the SEEMP.

The International Maritime Organisation (IMO) have currently set a 2% reduction per year on Carbon Intensity Index (CII) requirements until 2025, at which point the reduction will need to increase to get towards the overall IMO CO2 reduction goals of 2050.

Wärtsilä have reported the results of their CII Insight tool, which has predicted that when CII comes into force, about 45% of the fleet is forecast to be in category D, with a further 16% in category E. They further predict that, if nothing is done and assuming the IMO trajectory stays constant, by 2030, 81% of the bulker fleet, 57% of tankers and 80% of container ships will be in category E.

The most common approach to achieving compliance as of 2023 is to reduce the speed of the vessel through engine power limitation (EPL), which will reduce the amount of fuel per tonne per mile used, as ship resistance is proportional to the cube of the speed of the vessel. For some vessels this will be a short-term solution, for others the EPL required maybe significant, potentially meaning the engine will be operating well outside of its ideal parameters.

Apart from operational changes such as EPL, owners can implement technical efficiency improvements, and it’s here where the obvious installion of Windship Technology’s patented, high-performing rigs are most efficient. The performance of the Windship 36m rig has been calculated using computational fluid dynamics (CFD). This performance data can then be combined with the EEXI wind matrix to enable the reduction in EEXI for a given vessel to be assessed.

Windship Technology have conducted this assessment for a range of vessel DWT (Deadweight tonnage) to provide owners with a guide as to the powerful effect a single 36m rig could have on their ship. This technology can be used in conjunction with EPL if required to achieve compliance. A further benefit of this approach would be to consider adding a second rig, if in due course the CII required further reductions. Clearly the final EEXI reduction will be dependent on actual ship performance characteristics, however the graph provides a good indication of the potential.

Simon Rogers, Technical Director of Windship Technology is clear about the benefits: “This is a known issue that is fast coming down the track and one that ship operators must start addressing. What we have developed with our patented, high power rig design is a solution that works in tandem with existing EPL measures but greatly enhances performance. Our assessment is an EPL reduction of some 20-25% depending on the size of the vessel and not only are we extending the operational life of the ships that install Windship Technology rigs but we are making global shipping compliant and faster.”

Graham Harvey, Chief Executive of Windship Technology further added: “It’s very clear from the chart below the positive effects that installing our patented rigs has on performance. Owners, Operators and Charterers are all highly aware of the regulatory framework that is close to being imposed by the IMO and time is running out to achieve compliance. We are hosting a broad range of discussions with key players in the industry now and it’s very clear that Windship Technology is very much part of the solution going forward. We welcome further enquiries and discussion from interested parties.”

Methane emissions from the energy sector are 70% higher than official figures

The IEA’s Global Methane Tracker shows emissions from oil, gas and coal are on the rise again, underscoring need for greater transparency, stronger policies and immediate action.

Global methane emissions from the energy sector are about 70% greater than the amount national governments have officially reported, according to new International Energy Agency (IEA) analysis released on 23rd February 2022, underlining the urgent need for enhanced monitoring efforts and stronger policy action to drive down emissions of the potent greenhouse gas.

Methane is responsible for around 30% of the rise in global temperatures since the Industrial Revolution, and quick and sustained emission reductions are key to limiting near-term warming and improving air quality. Methane dissipates faster than carbon dioxide (CO2) but is a much more powerful greenhouse gas during its short lifespan, meaning that cutting methane emissions would have a rapid effect on limiting global warming.

The energy sector accounts for around 40% of methane emissions from human activity, and this year’s expanded edition of the IEA’s Global Methane Tracker includes country-by-country emissions from coal mines and bioenergy for the first time, in addition to continued detailed coverage of oil and natural gas operations. Methane emissions from the energy sector grew by just under 5% last year. This did not bring them back to their 2019 levels and slightly lagged the rise in overall energy use, indicating that some efforts to limit emissions may already be paying off.

“At today’s elevated natural gas prices, nearly all of the methane emissions from oil and gas operations worldwide could be avoided at no net cost,” said IEA Executive Director Fatih Birol. “The International Energy Agency has been a longstanding champion of stronger action to cut methane emissions. A vital part of those efforts is transparency on the size and location of the emissions, which is why the massive underreporting revealed by our Global Methane Tracker is so alarming.”

Last year, significant emissions were confirmed in Texas and parts of Central Asia, with Turkmenistan alone responsible for one-third of large emissions events seen by satellites in 2021. Relatively few major leaks were detected for the major onshore oil and gas producers in the Middle East.

Satellites have greatly increased the world’s knowledge of emission sources, and the IEA Global Methane Tracker incorporates the latest readings from satellites and other science-based measurement campaigns. While measured data continues to improve, the coverage provided by satellites is still far from complete: existing satellites do not provide measurements over equatorial regions, offshore operations, or northern areas such as the main Russian oil and gas producing areas.

Yet uncertainty over emissions levels is no reason to delay action on methane. Major reductions can be achieved with known technologies and with tried and tested policies that have been proven to work effectively. The Global Methane Tracker includes a new detailed policy explorer that provides examples of effective implementation and shows where these policies could be most impactful.

If all methane leaks from fossil fuel operations in 2021 had been captured and sold, then natural gas markets would have been supplied with an additional 180 billion cubic metres of natural gas. That is equivalent to all the gas used in Europe’s power sector and more than enough to ease today’s market tightness.

The intensity of methane emissions from fossil fuel operations range widely from country to country: the best performing countries and companies are over 100 times better than the worst. Global methane emissions from oil and gas operations would fall by more than 90% if all producing countries matched Norway’s emissions intensity, the lowest worldwide.

The Global Methane Pledge, launched in November by more than 110 countries at the COP26 Climate Change Conference in Glasgow, marked an important step forward. Led by the European Union and the United States, its participants agreed to reduce methane emissions from human activities – including agriculture, the energy sector and other sources – by 30% by 2030. However, more major emitters need to join. Of the five countries with the largest methane emissions from their energy sectors – China, Russia, the United States, Iran and India – only the United States is part of the Pledge as things stand.

“The Global Methane Pledge must become a landmark moment in the world’s efforts to drive down emissions,” said Dr Birol. “Cutting global methane emissions from human activities by 30% by the end of this decade would have the same effect on global warming by 2050 as shifting the entire transport sector to net zero CO2 emissions.”

European Commission Executive Vice-President Frans Timmermans said:

“Methane is the second biggest contributor to global warming. Rapidly cutting methane emissions is therefore a key part of our efforts to tackle the climate crisis. As established in the Global Methane Pledge, we need more precise data on actual methane emissions. By measuring, reporting, and verifying, we will know where emissions cuts are most urgent. The IEA’s report underscores the necessity of this effort.”

US Special Presidential Envoy for Climate John Kerry said:

“Cutting methane pollution is the fastest way to mitigate climate change, and cutting wasteful venting, leaking, and flaring from oil and gas systems is the fastest way to cut methane. The IEA’s new report provides important insight on the scale of this climate action opportunity. It also highlights the need for governments to enhance the accuracy of their methane emissions data in national inventories and to act together to cut emissions at least 30% by 2030 under the Global Methane Pledge.”

Canada’s Natural Resources Minister Jonathan Wilkinson said:

“Combatting climate change means tackling methane emissions in Canada and around the world. Canada has set a target of reducing methane emissions by at least 75% below 2012 levels by 2030, and has put in place regulations to help achieve that target. This makes us the first country to sign up to the IEA's call to action. We’re working with the provinces and territories, Indigenous partners, industry and labour to put workers front and centre in the global effort to cut methane emissions.”

Lars Carlsson of Windship Technology said:

"It is obvious that emissions from shipping are increasing and that emission volumes from methane are hidden. There is only one way forward to save our world: A Zero Emission Target and the best solution at present is the Windship Technology Project where Windships could reduce emissions and fuel costs by about 75% already now and reach Zero Emissions by 2040."

Contact us on info@windshiptechnology.com to understand more about the Windship Technology and how we can address this issue for the shipping industry.

Click here to read the full IEA Global Methane Tracker report.

Windship Technology wins Motorship award

Honouring and recognising innovative low emissions vessels partnerships in zero emissions race, the Motorship award winner was chosen from a shortlist of four projects. The four finalists presented their projects at the Propulsion & Future Fuels 2021 conference, 2-4 November and Windship Technology were delighted to be announced as the winner.

Graham Harvey, CEO of Windship Technology introduced the company’s Zero Emission Solution to a conference audience for the first time in the Motorship Award session on day one of this year’s conference. About the award, Graham said, “On behalf of all of the Windship Technology team, we are delighted to win this award. It arrives on the same day that we announced verification of the Windship Technology Solution by classification society DNV. Eight years of hard work by the team. Thank you for this award.”

Windship Technology reaches milestone for its Zero Emission concept for shipping

Windship Technology’s combination of wind power, efficient electric drive train, carbon capture and optimisation all work together to achieve new Zero Emission concept.

2nd November 2021: Windship Technology can today reveal that its Zero Emissions solution for shipping has been independently assessed by classification society DNV.

By using data provided by Windship Technology – a British innovation company – DNV has performed an independent computer-based analysis of the concept’s emissions abatement potential.

Speaking about this significant development, Simon Rogers, Technical Director of Windship Technology stated: “Today everything changes. The world now has a True Zero Emission solution for the shipping industry with technologies that are available today and a commercial case rooted in economic sustainability. It’s a significant inflection point for the shipping industry. From a technical standpoint, Windship Technology is now verified.”

DNV’s analysis of Windship Technology’s True Zero Emission solution for shipping was extensive and thorough, based on a holistic approach factoring sound scientific practices and the data provided by Windship Technology.

Using the COSSMOS analysis modelling suite for the drivetrain and based on the information provided, DNV assessed that Windship Technology’s solution captures 100% of the CO2 generated whilst providing 49% fuel savings.

Per Marius Berrefjord, Senior Vice President and Business Development Leader at DNV Maritime, said: “After extensive testing and modelling, the results from our analysis of Windship Technology’s innovative solution confirm that this design can provide a zero-emission system with the capability to save 49% of the expected fuel consumption of an Aframax Tanker.”

Brian Sweeney of Calix Limited, said “Calix’s LEILAC Technology can produce very highly reactive lime with zero emissions. In our RECAST invention, this lime is used on a ship to absorb CO2, clean the exhaust gases and supplement power production. Given this independent verification of our modelling we are keen to engage in the planned demonstration programme. We look forward to working with Windship to deliver this shipping solution globally.”

Emeritus Professor Philip Wilson, Professor of Ship Dynamics at the Ship Science Department at the University of Southampton, said: “An incredible conclusion to a deep study by a leading registrar and classification society of ships. The system that delivers a true zero emission ship demonstrated by using real data is a remarkable and a humbling output to all the world ship operators, ship builders and ship designers. This has to be given a fanfare from the highest mountains and a wake-up call to the industry as a whole.”

In due course, Windship Technology will issue further information on its cost-efficiencies in relation to future fuels showing comparative costs. Windship will demonstrate zero CO2 emissions, NOx, SOx and particulate matters and VOC (volatile organic compounds) with a clean exhaust emitting non-toxic nitrogen, oxygen and water. This will further bolster the economic case and provide solutions for commercial fleet operators, shipbuilders and charterers.

-ENDS-

Addendum:

The baseline for DNV’s evaluation was annual live AIS data and full operational profiles for 20 Aframax vessels in operation on US-Europe routes, 12 times each per annum. Windship Technology’s rig combines wind power, solar electricity, modular diesel electric drive with Calix RECAST carbon capture and waste-heat recovery. DNV has shown this to reduce total operational fuel consumption by 49% (including port operations in laden and ballast condition) whilst emitting zero CO2.

Furthermore, with EEXI legislation coming in 2023, Windship Technology’s solution has the potential for further significant fuel savings with zero CO2 emissions if the average operational speeds come down from 12 knots.

For Media Enquiries:

Kate Porteous, New Forest Creative | Tel: +44 7977 470710 | kate@newforest-creative.co.uk

Notes to Editors:

Windship Technology Ltd is a British company with the solution for one of the world’s main causes of CO2 emissions: commercial shipping. Worldwide, a fleet of 37,000 vessels operate largely unseen, with a total CO2 output accounting for 3% of global emissions. By 2050, commercial shipping is on course to constitute up to at least 10% of the world’s CO2 emissions if left unchecked.

Fusing the expertise of world-leading ship designers and shipping industry veterans, Windship Technology Ltd has a fully patented triple rig wing design and a whole-ship solution harnessing wind technology, carbon capture, solar energy, renewable power, weather routing, hull design and highly innovative engine design.

Windship Technology is essential to the global transportation revolution. The shipping sector is ready for change. Windship Technology has the solution to make it happen.