Windship Technology wins Motorship award

Kate Porteous2021-12-16T14:58:40+00:00Honouring and recognising innovative low emissions vessels partnerships in zero emissions race, the Motorship award winner was chosen from a shortlist of four projects. The four finalists presented their projects at the Propulsion & Future Fuels 2021 conference, 2-4 November and Windship Technology were delighted to be announced as the winner.

Graham Harvey, CEO of Windship Technology introduced the company’s Zero Emission Solution to a conference audience for the first time in the Motorship Award session on day one of this year’s conference. About the award, Graham said, “On behalf of all of the Windship Technology team, we are delighted to win this award. It arrives on the same day that we announced verification of the Windship Technology Solution by classification society DNV. Eight years of hard work by the team. Thank you for this award.”

Windship Technology reaches milestone for its Zero Emission concept for shipping

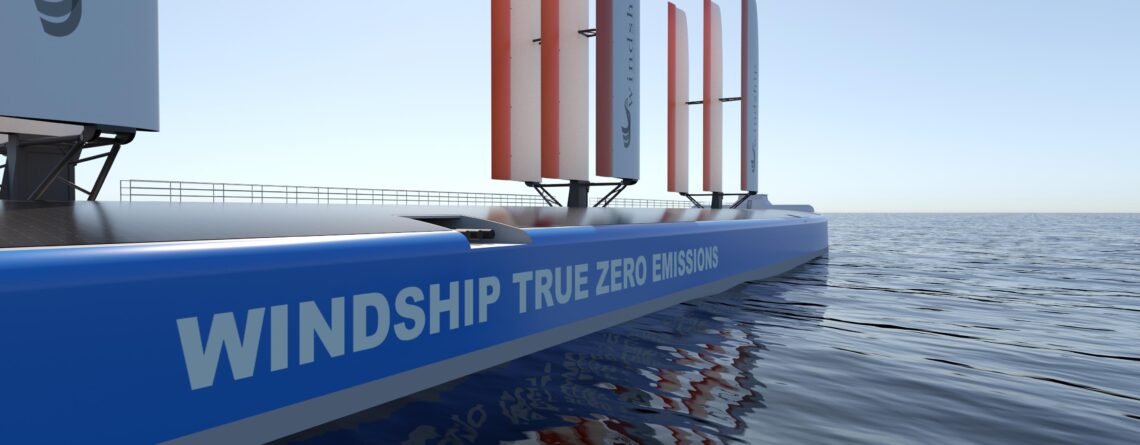

Kate Porteous2021-12-16T14:19:56+00:00Windship Technology’s combination of wind power, efficient electric drive train, carbon capture and optimisation all work together to achieve new Zero Emission concept.

2nd November 2021: Windship Technology can today reveal that its Zero Emissions solution for shipping has been independently assessed by classification society DNV.

By using data provided by Windship Technology – a British innovation company – DNV has performed an independent computer-based analysis of the concept’s emissions abatement potential.

Speaking about this significant development, Simon Rogers, Technical Director of Windship Technology stated: “Today everything changes. The world now has a True Zero Emission solution for the shipping industry with technologies that are available today and a commercial case rooted in economic sustainability. It’s a significant inflection point for the shipping industry. From a technical standpoint, Windship Technology is now verified.”

DNV’s analysis of Windship Technology’s True Zero Emission solution for shipping was extensive and thorough, based on a holistic approach factoring sound scientific practices and the data provided by Windship Technology.

Using the COSSMOS analysis modelling suite for the drivetrain and based on the information provided, DNV assessed that Windship Technology’s solution captures 100% of the CO2 generated whilst providing 49% fuel savings.

Per Marius Berrefjord, Senior Vice President and Business Development Leader at DNV Maritime, said: “After extensive testing and modelling, the results from our analysis of Windship Technology’s innovative solution confirm that this design can provide a zero-emission system with the capability to save 49% of the expected fuel consumption of an Aframax Tanker.”

Brian Sweeney of Calix Limited, said “Calix’s LEILAC Technology can produce very highly reactive lime with zero emissions. In our RECAST invention, this lime is used on a ship to absorb CO2, clean the exhaust gases and supplement power production. Given this independent verification of our modelling we are keen to engage in the planned demonstration programme. We look forward to working with Windship to deliver this shipping solution globally.”

Emeritus Professor Philip Wilson, Professor of Ship Dynamics at the Ship Science Department at the University of Southampton, said: “An incredible conclusion to a deep study by a leading registrar and classification society of ships. The system that delivers a true zero emission ship demonstrated by using real data is a remarkable and a humbling output to all the world ship operators, ship builders and ship designers. This has to be given a fanfare from the highest mountains and a wake-up call to the industry as a whole.”

In due course, Windship Technology will issue further information on its cost-efficiencies in relation to future fuels showing comparative costs. Windship will demonstrate zero CO2 emissions, NOx, SOx and particulate matters and VOC (volatile organic compounds) with a clean exhaust emitting non-toxic nitrogen, oxygen and water. This will further bolster the economic case and provide solutions for commercial fleet operators, shipbuilders and charterers.

-ENDS-

Addendum:

The baseline for DNV’s evaluation was annual live AIS data and full operational profiles for 20 Aframax vessels in operation on US-Europe routes, 12 times each per annum. Windship Technology’s rig combines wind power, solar electricity, modular diesel electric drive with Calix RECAST carbon capture and waste-heat recovery. DNV has shown this to reduce total operational fuel consumption by 49% (including port operations in laden and ballast condition) whilst emitting zero CO2.

Furthermore, with EEXI legislation coming in 2023, Windship Technology’s solution has the potential for further significant fuel savings with zero CO2 emissions if the average operational speeds come down from 12 knots.

For Media Enquiries:

Kate Porteous, New Forest Creative | Tel: +44 7977 470710 | kate@newforest-creative.co.uk

Notes to Editors:

Windship Technology Ltd is a British company with the solution for one of the world’s main causes of CO2 emissions: commercial shipping. Worldwide, a fleet of 37,000 vessels operate largely unseen, with a total CO2 output accounting for 3% of global emissions. By 2050, commercial shipping is on course to constitute up to at least 10% of the world’s CO2 emissions if left unchecked.

Fusing the expertise of world-leading ship designers and shipping industry veterans, Windship Technology Ltd has a fully patented triple rig wing design and a whole-ship solution harnessing wind technology, carbon capture, solar energy, renewable power, weather routing, hull design and highly innovative engine design.

Windship Technology is essential to the global transportation revolution. The shipping sector is ready for change. Windship Technology has the solution to make it happen.

Making Waves – The Future of Shipping

Kate Porteous2021-09-19T13:28:42+00:00The UK Chamber of Shipping and the British Ports Association are proud to present a showcase of the maritime industry’s transition to a smarter, cleaner future in their exclusive new programmes created in partnership with CWP. The International Maritime Organization hosted a premier screening for sector delegates on 13th September during London International Shipping Week, and both programmes are now available to view in full online.

Committed to a cleaner future, the global shipping industry is undergoing a transformative journey. ‘Making Waves: The Future of Shipping’, produced in collaboration with the UK Chamber, shines a spotlight on the efforts already underway and sends a clear call for continued ambitious action in order to decarbonise. The programme charts the sector’s rapid progress in innovation - from alternative fuels to new technologies, and gives voice to those calling for increased regulation in order to deliver a sustainable future.

Intrinsic to our domestic shipping industry are Britain’s ports; our gateways to and from the world, playing an irreplaceable role in our economy and in our communities. ‘Gateways to Growth’, delivered in partnership with the BPA, reveals the people, communities and organisations behind them, highlighting ports’ vital contribution to society, and the innovations shaping their pathway to net zero.

The programmes feature comment from industry leaders and thought makers, including Robert Courts MP and Baroness Brown, as well as stories from organisations and professionals that are driving efforts across both sectors towards a positive future.

Among the organisations featured are; the American Bureau of Shipping (ABS), Artemis Technologies, Bibby Marine, BMT, DNV, EPSRC, Harwich Haven Authority, HFW, the International Maritime Organization (IMO), ION, Jacobs (Team 2100), Lean Marine, Lloyd’s Register, MarRI-UK, Montrose Port Authority, Newcastle University, Norton Rose Fulbright, Orkney Harbour Authority, PD Ports, Port of Dover, Port of Milford Haven, Port of Workington, Portsmouth International Port, Quadrise Fuels, Resilience Shift / ARUP, the Sustainable Shipping Initiative (SSI), Sutton Harbour Group, Trafigura, TT Club, Wärtsilä, Windship Technology and Windward.

Bob Sanguinetti, Chief Executive of the UK Chamber of Shipping said: “We are delighted that our partnership with CWP has provided a platform to showcase the huge efforts underway across the industry to embrace the challenges and opportunities we face in reducing emissions. We hope this will provide further impetus for innovation and progress as we collectively take action on climate change”.

Richard Ballantyne, Chief Executive of the British Ports Association commented: “Our ports are a source of great national pride. There is much to celebrate in their value to communities and industry across the UK, however we must remain committed to the country’s net zero target and take inspiration from some of the stories featured in Gateways to Growth”.

Max Smith, Managing Director, CWP said: “With the Decade of Action for sustainable solutions now fully underway, it’s been hugely encouraging to experience the sense of optimism from every corner of the maritime industry, and to portray this in these programmes. There is no doubt that the industry is facing a grand set of challenges, but this is a highly motivated maritime community, and we are excited to share some of their stories.”

Windship Technology are delighted to feature. Watch the programme in full on: www.makingwaves.ukchamberofshipping.com

Windship Technology secures coveted Approval in Principle for innovative triple-wing design from DNV.

Kate Porteous2021-09-06T14:54:56+00:00Confirmation of the key element in the Windship True Zero Emission Solution - now ready to be implemented.

6th September 2021, London: Windship Technology, Britain’s leading True Zero Emission company for the shipping industry today announces their patented triple-wing rig has received a coveted ‘Approval in Principle’ (AiP) status from shipping classification society DNV.

This significant milestone in the company’s history is the result of years of design iteration work combined with the use of cutting-edge CFD to refine the wings before extensive wind tunnel testing and analysis by independent third parties. Each wing has trailing edge flaps that allow for optimisation of the motive force produced for a variety of incident wind angles and, crucially, allow the rigs to produce the highest power density of any current wind-powered solution. With three rigs set, they can produce all the power required to sail an 80,000 DWT ship on the main long transoceanic routes.

Speaking about the classification, Simon Rogers, Technical Director at Windship Technology stated: “This is the classification that changes everything. Now it is abundantly clear that the shipping industry has a workable solution to its significant emissions issues. Fleet owners and charterers have a zero emissions option with Windship Technology’s whole-ship design that is set to revolutionise the industry and the need for these wing solutions has never been more than now. With the Energy Efficiency Existing Ship Index coming into force on 1st January 2023, the clock is ticking on the shipping industry. Windship Technology is the stand-out solution and we welcome the Approval in Principle from DNV whom we have worked with efficiently and expediently in achieving this classification.”

Windship Technology is leading the innovation not only in rigs but also in its overall solution for Zero Emission shipping. The design starts with the rigs, constructed from composite materials to reduce weight at height, and goes further with an incorporated diesel electric drive featuring a full carbon capture system that dramatically reduces fossil fuel consumption whilst eliminating NOx, SOx and particulate matter and zero CO2.

The wings deployed on vessels are located on a steel cruciform base which provides the intersection with the ship and also house the lifting and lowering mechanism – especially important for port access and bridge height clearance. The rigs can be lowered either fore and aft or over the ship’s side as required for loading and unloading operations. Whilst underway, the rigs are automatically controlled, rotating to gain the greatest motive advantage from the available wind power.

As the Approval in Principle for Windship Technology’s tri-rig was announced, Hasso Hoffmeister, Senior Principal Engineer, DNV Maritime said: “As shipping’s carbon trajectories head towards zero and the EEXI and CII are set to tighten requirements – the maritime industry needs new options to reduce emissions. At DNV we want to support our customers by making sure that when they are looking to make efficiency gains, they have well proven and well tested options. This is why we are so pleased to be working with Windship Technology, to help them build confidence in their Wind Rig system through the application of expertly verified models and data, based on our long-standing and globally accepted rules

Graham Harvey, Chief Executive of Windship Technology welcomed the news; “This is a terrific milestone for the whole team at Windship Technology and we are now in a position to capitalise on the multiple discussions that we have been having with owners and charterers who are all looking for long-term solutions. It’s wonderful that a truly innovative, British company is leading the way in finding a true zero emission solution and we would like to thank the team at DNV for their assistance in helping us bring this much-needed solution a step closer to reality.”

As seen in Raconteur, ‘Supply Chain Resistance’ – The Sunday Times, 5th Sept 2021.

Kate Porteous2021-09-06T09:47:38+00:00On the road to net-zero logistics

“When it comes to rethinking ship design, the ‘True Zero Emission concept from British company Windship Technology promises more disruptive innovation. Dubbed ‘the Tesla of the seas’, its triple-wing rigs harness the power of the wind, with the look of a 21st-century clean-tech clipper.” Jim McClelland.