Leading expert knowledge and CFD analysis

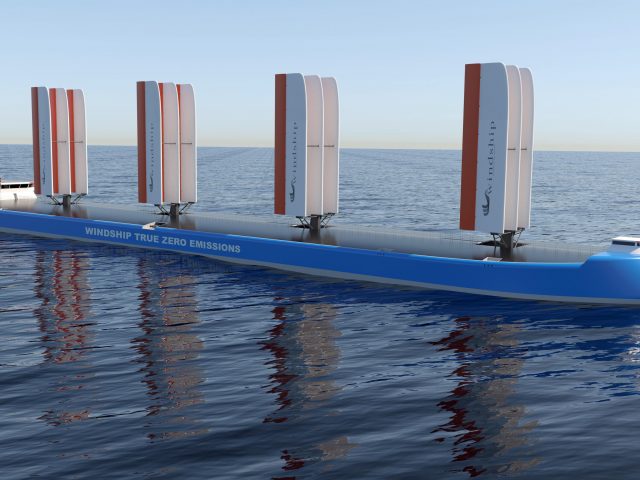

Windship and DNV unveil ‘first true zero-emissions’ design

UK company claims new wind-powered system is the "Tesla of the seas". Windship Technology has revealed what it claims is the world's first truly zero-emissions ship system. The UK company has brought Norwegian classification society DNV on board to help develop a wind-powered design it refers to as the "Tesla of the seas".... "Per Marius Berrefjord, senior vice president at DNV, called the Windship team "experienced professionals". He said the project aims to help bring the entire shipping industry to "true zero" in terms of emissions. "Windship is supplying information in a fully transparent manner, and DNV will ensure a thorough verification process. We are looking forward to dive deeper into the very interesting technology presented by Windship," the DNV executive added. Windship is now looking to seal commercial partnerships with major shipowners, operators and investors, the UK company said. The Windship board includes former Concordia Maritime chief executive Lars Carlsson. The ex-tanker executive said: "The industry cannot sit back any longer. The clock is ticking and regulation will force a new approach for an industry that is traditionally hesitant to change." He added shipping is not fit for purpose for the future. Carlsson has been advocating wind power for a number of years. He said in 2019 that owners should be using all known fuel-saving methods, including wind propulsion, lower speeds, design and operational optimisation and biofuels derived from waste. And he called for new vessels to be built with anti-corrosion coated steel to give them a longer trading life of 50 years, a global fossil-fuel tax to encourage sustainable investment and the creation of a carbon exchange trading market.Read the full article from Tradewinds > Tradewinds subscribers, click here to find out more from Tradewinds >

The ‘Tesla of the Seas’ – pioneering British company, Windship Technology unveils first True Zero Emission ship design

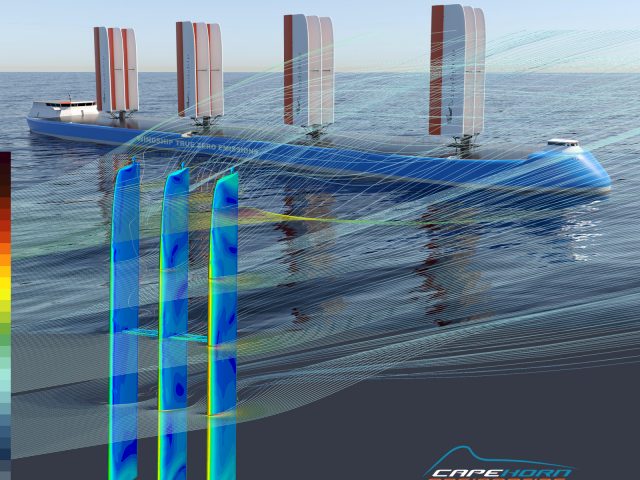

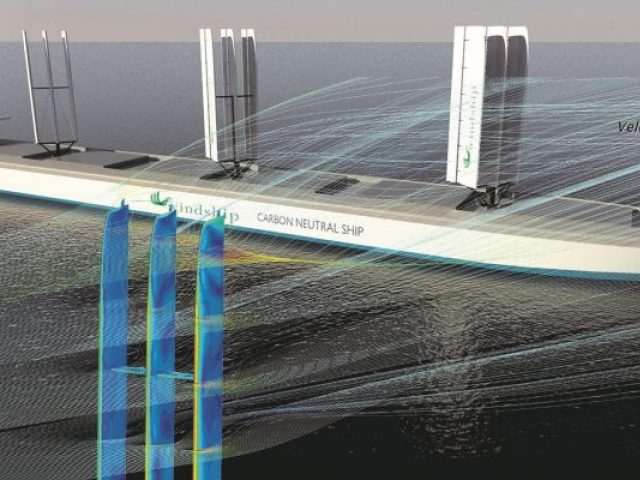

Use of fluid mechanics improves the efficiency of wind-assisted ships

UK-based Cape Horn Engineering has reported a two-digit percentage improvement in the aerodynamic performance of a vessel’s solid wing assembly via the use of Computational Fluid Dynamic (CFD) programme. The use of Wind Propulsion Technology (WPT) such as rigid wings, sails, kites, Magnus rotors on some vessels like bulk carriers and tankers have the potential of fuel savings and emission reductions around 10-30%.

Cape Horn Engineering said it is supporting one of its clients, Windship Technology, on a solid wing power concept that is being developed by a consortium of key players in the global shipping industry.

“We are extremely proud to be part of the team led by Windship Technology for this exciting project, running a CFD programme to further improve the design of the solid wings,” said Rodrigo Azcueta, managing director of Cape Horn Engineering.

“One of the key focuses of our project is to provide a clearer, unbiased and more detailed analysis of the new technologies available. The analytical evidence provided will give businesses a clearer understanding of the potential savings that can be realised with the implementation of the green propulsion systems. Without significant mitigating action it is projected that the global shipping industry could account for almost a fifth of carbon emissions by 2050,” Azcueta said.

Read the full Seatrade Maritime News article: here.

The ancient technology getting a second wind – BBC interview

People fixing the world

Our Technical Director, Simon Rogers, was interviewed by Nick Holland on the BBC World Service in May 2020, talking about how the Windship Technology solution can save over 70% fuel and help bulk carriers significantly cut emissions too.

Old ships, powered by the wind, are sailing small amounts of cargo around the world again to help cut pollution. Some of them were built more than 100 years ago.

The shipping industry moves 80% of traded goods around the planet. But the diesel engines that propel modern cargo ships through the oceans burn the dirtiest type of fuel.

Nick Holland speaks to sailors and brokers who, for the sake of the environment, are breathing new life into these vintage vessels.

And he hears how new types of sails could get monster-sized modern cargo ships using the wind as well.

Wind Tunnel Testing

Further Windship Technology testing confirms at least 30% annual fuel and emissions saving for commercial shipping.

Key industry experts, prospective clients in the shipping, commodities and petrochemical sectors together with UK government officials attended the Mitchell – Wolfson Unit Wind Tunnel at the University of Southampton to view the testing of the most recent Windship Technology model in February 2020. The wind tunnel test findings further validated the results of the latest Windship Technology CFD testing. https://www.youtube.com/watch?v=sWH8FrVltAA

The patented UK designed Windship rig system is consistently regarded as the most powerful fuel and emission saving wind system in the market, which will materially help the shipping industry closer towards achieving its 50% reduction in emissions by 2050, as required by the IMO. That organisation has recently acknowledged wind propulsion as one of the solutions for the shipping industry to meet decarbonisation targets, as outlined in the MEPC_C75_Inf26.

The solution, known as the Windship Auxiliary Sail Propulsion System (WASPS), uses fixed wing sail technology, whereby three 35-metre high masts installed on the deck of a vessel will each have three aerodynamic wings fitted (pictured) to exploit the power of the wind. The system allows reductions in engine power to be made in order to achieve the same speed and so maximise fuel-saving and emissions reduction.

Without significant mitigating action it is projected that the global shipping industry could account for almost a fifth of carbon emissions by 2050. Windship’s solution will be able to save a minimum of 30% of the CO2 emissions annually.

The Windship system combined with reduced engine revolutions and other ship optimisation could save up to 80% of fuel and emissions. This aspirational approach will bring closer the possibility of a Carbon Neutral ship well in advance of 2050.

Simon Rogers, Technical Director said, “We are delighted with the results of the wind tunnel testing and they further illustrate how we will help the shipping industry to make a significant reduction in CO2 emissions. We are in discussions with potential development partners to build and install the prototype system.”

Net Zero Emissions Target

As featured in TradeWinds in July 2019, Tanker shipping veteran and long-term proponent of wind propulsion, Lars Carlsson, is proposing a campaign to shift shipowners toward net-zero emission status as the industry begins to get to grips with the IMO target for a 50% cut by 2050.

Carlsson, current director of Windship Technology, a former Managing Director of Concordia Maritime and Chairman of INTERTANKO, wants the industry to set up a World Shipping Board within the IMO to lead a push towards net-zero emissions.

The board, comprising up to 10 people, could "guide us through the coming years' transition, with strong recommendations and executive power, by forcing authorities to legislate for immediate reduction of harmful emissions," he argues in a letter to Trade Winds.

Carlsson, who is now a director at Windship Technology, suggests giving the board 100 votes at the IMO so it can propel legislation through the United Nations organisation for net zero emissions by 2040. Windship is a company developing wind sail rigs for bulkers and tankers aimed at cutting fuel use by 45%.

'Inexcusable delay'

"Kitack Lim, the secretary general of IMO, has a lot of integrity if he could just escape from half of his 200 country delegates' votes in IMO," Carlsson writes.

"Net zero emissions in shipping can be achieved by a determined investment in carbon-neutral vessels. But any target of action as late as 2050 is an inexcusable delay, postponing necessary climate action to the next generation so that we in our generation can enjoy our life and our perks undisturbed by harsh realities," he argues.

Click here to read the full article (subscription required).

Photo credit: Tradewinds

Windship Director races in the Rolex Fastnet Race 2019

Simon Rogers, Technical Director of Windship Technology, and his family participated in the Rolex Fastnet Race 2019. The crew of Assent, a Contessa 32 and the smallest IRC boat in the Race arrived safely in Plymouth at 0430 on 9th August 2019 after an “epic night of lightning, high winds and waves.”

Huge congratulations to the crew (from left): Kit Rogers, Hattie Rogers, Jonah Rogers and Simon Rogers.