Windship Technology shortlisted for The Motorship Award

Kate Porteous2021-04-13T14:09:31+00:00We are delighted to announce that Windship Technology has been shortlisted for The Motorship Award.

The shortlist is drawn up through a combination of self-nomination and recommendations made by the event steering committee, which includes representatives from major ship owners, technology providers, class societies and ship owner organisations. The shortlisted entrants will present their projects at The Motorship’s Propulsion & Future Fuels Conference 2021, 2-4 November, Hamburg, Germany, where the overall winner will be decided by a delegate vote.

The conference will cover a range of topics with emphasis on the next steps to 2030 and 2050; and an in-depth analysis of ship operators’ future fuel considerations with sessions featuring expert presentations from a selection of fuel and equipment manufacturers, policy makers, safety experts, shipowners, and class societies.

2021 marks the 42nd anniversary of Motorship Conferences, making Propulsion & Emissions the longest running technical conference in the maritime sector. The conference provides senior executives with a meeting place to learn, discuss and share knowledge of the latest developments in efficient propulsion technology and low flashpoint, low carbon fuels. It is a must-attend event for CEOs and technical directors from ship owning/operating and management companies, ship design and ship building senior executives, sector specialists from fuel, equipment and technology suppliers plus senior management and advisers from classification and policy-making organisations.

The conference features strong support and chairmanship from two of the sectors heavy weight associations: BIMCO, whose shipowner members represent more than 60% of global tonnage, and the German shipowner association VDR, headquartered in Hamburg and representing a fleet of 2,324 ships with a combined gross tonnage of 57.5 million.

The Motorship has been published since 1920 and is the longest running technical title within the marine sector. It provides insight for marine technology professionals in print, online and through regular eNews and social media. With a monthly combined audience of 34,959 this title underpins the success of its sister events.

The Motorship Conference, Propulsion & Future Fuels, is the one event you should attend to keep up to date with the latest developments in marine technology, legislation and other key issues whilst also offering fantastic networking opportunities!

For information on booking your delegate place, call +44 1329 825335 or email conferences@propulsionconference.com. We look forward to seeing you there.

Graham Harvey appointed as Chief Executive of Windship Technology

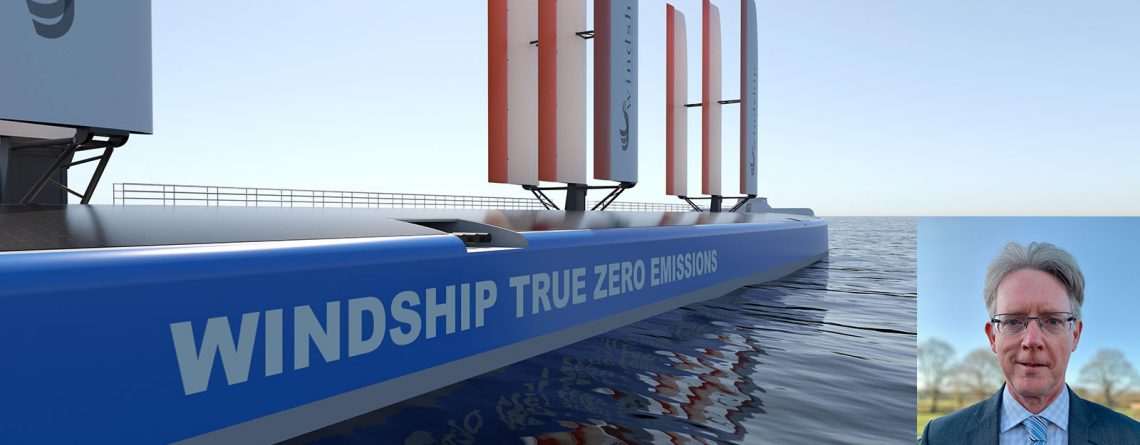

Kate Porteous2021-03-22T10:20:08+00:00Graham Harvey appointed Chief Executive of Britain’s leading True Zero Emissions solution company for the shipping industry.

22nd March 2021, London: The Board of Directors of Windship Technology, Britain’s leading True Zero Emission company for the shipping industry, are delighted to confirm the appointment of Graham Harvey as Chief Executive Officer. Graham’s remit will be to convert the significant progress that has been made in the overall Windship Technology solution and to commercialise the proposition.

Graham has spent a lifetime in and around the marine industry having studied Ship Science at the University of Southampton. A member of the Royal Institute of Naval Architects, Graham’s career saw him rise to Head of Technology at SP Systems Limited, a privately-owned manufacturer of advanced composite materials, before assuming the Managing Director role in 2005. Following acquisition by Gurit and subsequent merger with three other composite companies, Graham assumed the position of General Manager of Engineered Structures before becoming General Manager of Composite Components until 2015.

Since then, he has run a successful Management and Engineering consultancy business with activities including securing patents on a novel application for composite structures in a marine environment, business development support to a precision composite component manufacturer, interim MD for a superyacht manufacturer, engineering consultancy and acting as an adviser to a start-up composite business.

Robert Elliott, Chairman of Windship Technology commented: “We welcome Graham as our new Chief Executive and herald a new structure in our business with a focus on taking Windship Technology’s patented rig solution and whole-ship True Zero Emission design to market. The opportunity now for ESG-aware investors, be they in the industry, private equity or at government level, is compelling and with a formal structure in place, led by Graham, we feel strongly that progress will be made swiftly. It’s a very exciting time for Windship Technology and Graham has absolutely the right skill-set to deliver on the company’s vision.”

Graham Harvey, Chief Executive of Windship Technology added: “I am delighted to have been appointed as Chief Executive of Windship Technology and look forward to harnessing the energy and enthusiasm within the company that has started to deliver a world-beating solution. This is British innovation at its finest, thinking globally and solving one of the world’s great challenges of our time. I am convinced that Windship Technology is the only company in the world right now capable of achieving the complete elimination of CO2, NOX, SOX and particulate matter to True Zero through our innovative and patented solution for shipping, so my role is to set the strategy and navigate the corporate waters ahead. I look forward to working with the team and thank the Board of Directors for their support.”

Windship Technology confirms attendance at the Society of Maritime Industries Conference 2021

Kate Porteous2021-03-09T10:59:00+00:00Technical Director, Simon Rogers announced as speaker to unveil the first 100% True Zero Emission solution for shipping to the industry.

8th March 2021, London: Windship Technology, Britain’s leading True Zero Emission company for the shipping industry is confirmed to unveil designs in a technical briefing to the shipping industry on Wednesday 17th March 2021 at the Society of Maritime Industries’ Annual Conference.

The Conference, Chaired by Rear Admiral Rob’s Stevens CB is themed around the refresh of the National Shipbuilding Strategy, currently underway within Government, supported by the industry and the Maritime Enterprise Working Group and will explore how maritime and industry stakeholders can best cross-collaborate throughout the UK to maximise opportunities.

The title ‘Building the future of the UK’s shipbuilding enterprise’, reflects the broadening of the National Shipbuilding Strategy to increase the focus on commercial shipbuilding and the supply chain. In attendance will be The Rt Hon Ben Wallace MP, Shipbuilding Tsar and Secretary of State for Defence alongside fellow MPs and a host of companies involved in revolutionising and innovating the shipping industry. Windship Technology’s inclusion is a significant recognition of the company’s work to date in delivering a whole-ship design to deliver a True-Zero Emission solution.

Simon Rogers, Technical Director of Windship Technology commented: “It is vital that Windship Technology leads the debate on True Zero Emissions for shipping. As the only company in the world right now capable of achieving the complete reduction of CO2, NOX, SOX and particulate matter to True Zero through our innovative and patented solution for shipping, it is right that we are engaging with the industry at events such as these. We are delighted to showcase our progress and look forward to supporting the Society of Maritime Industries who are pushing hard to raise the bar of the industry and involve government in a partnership for progress.”

Robert Elliott, Chairman of Windship Technology added: “Shipping is rapidly approaching a crossroads where decisions have to be made that will affect the next 25 years of commercial activity. Legislation is largely against asset owners who are unwilling to adopt True Zero Emission technologies, but the good news is that there are many large carriers and leasers of commercial vessels who are demanding a new solution. We know that Windship Technology has the best solution on the market for commercial bulk carriers serious about their environmental commitments and we look forward to supporting the Society of Maritime Industries at their Annual Conference.”

For more details about the Annual Society of Maritime Industries Conference 2021 please see the following link: https://smievent.com/annual-conference/

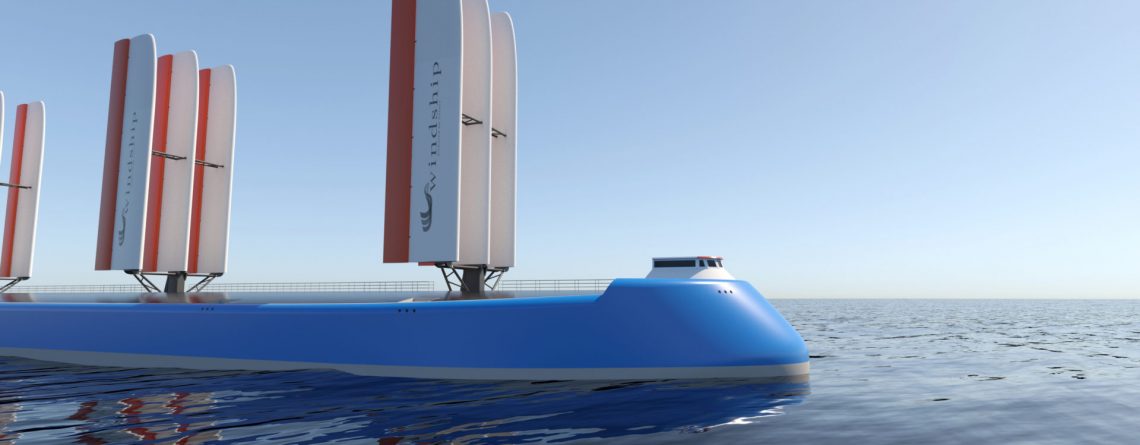

Pioneering British company, Windship Technology powers first True Zero Emission ship design with high performance rig technology

Kate Porteous2021-03-01T17:54:10+00:00Wolfson Unit Report confirms fuel and efficiency savings from the innovative rig powering the first 100% True Zero Emission solution for shipping.

1st March 2021, London: Windship Technology, Britain’s leading True Zero Emission company for the shipping industry, can today confirm the findings from the world leading Wolfson Unit of the University of Southampton following a detailed study into its innovative and patented triple wing rig.

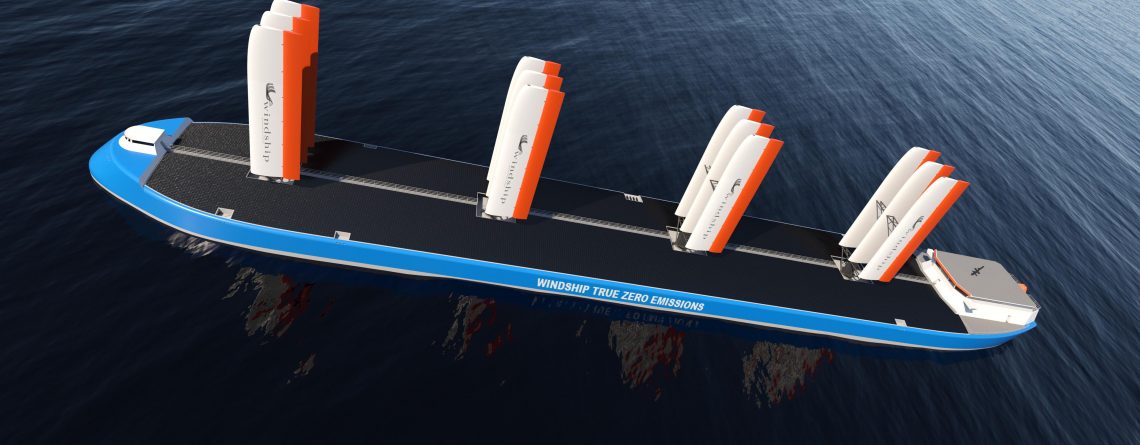

After extensive testing and VPP work conducted at the Wolfson Unit and further Computational Fluid Dynamics and aerodynamic performance optimisation conducted by Cape Horn Engineering, it has been confirmed that an appropriately rigged commercial vessel will achieve savings of fuel and corresponding emissions at a conservative 30% per annum via the rigs alone.

The Wolfson Unit report summarised performance predictions in terms of thrust reductions or effective power reductions for a 125,000DWT vessel with two different combinations of rig devices and in application, the rigs are essential to the effectiveness of Windship Technology’s whole ship True Zero Emission design.

Speaking about the report, Simon Rogers, Technical Director of Windship Technology commented: “We were delighted to receive this confirmation from the Wolfson Unit after extensive testing and we always knew that the rigs would be the bedrock from which the whole-ship design could be developed. What we now know for sure is that we have the best practical solution for commercial bulk carrier companies that wish to take their climate commitments seriously. The rigs are lower in height with vastly more thrust than single-masted technology. Combined with our whole ship design, Windship Technology can eliminate CO2, NOX, SOX and particulate matter to True Zero through incorporating large solar arrays, carbon capture, optimised hull shapes and specialised weather routing software into the overall design package.”

The invention protected by these patents is the use of rigid aerofoil sails for bulk cargo vessels, typically raw mineral carriers (coal, grain, ore, cement, alumina, bauxite et.) or large commercial oil tankers. The global patents cover multiple pairs of leading and trailing aerofoil sections supported on a rotatable spar, and the angular position of the spar can be adjusted as required, as can the angular position of the trailing sections.

The 48m Windship Technology rig is stowable on deck through a unique, innovative stowage solution to aid port navigation and cargo handling. Its composite structure is borne out of technology and design from the wind turbine industry, ensuring reliability and longevity of greater than 25 years.

Dr-Ing. Rodrigo Azcueta, Managing Director of Cape Horn Engineering is convinced by Windship Technology’s solution saying: “We analysed a multitude of wing assembly shape configurations for Windship Technology in varying wind conditions. In total, almost one thousand, high-fidelity CFD simulations were performed. These simulations were extremely valuable for improving the geometries of the wing assembly and through our detailed investigations at Cape Horn Engineering, a double-digit gain in aerodynamic performance was obtained. Windship Technology’s fixed wing sail systems are highly engineered and have been designed for optimal performance. We are extremely proud to be involved with the technical team on this project.”

Windship Technology is now starting to engage with interested parties from both the shipping industry and investment circles. Significant ESG-focused investors are recognising the benefits of True Zero Emission shipping. Furthermore, asset owners and leasing companies such as oil and commodity majors and ship owners are seeking to protect their significant investments in the face of legislation and shareholder sentiment.

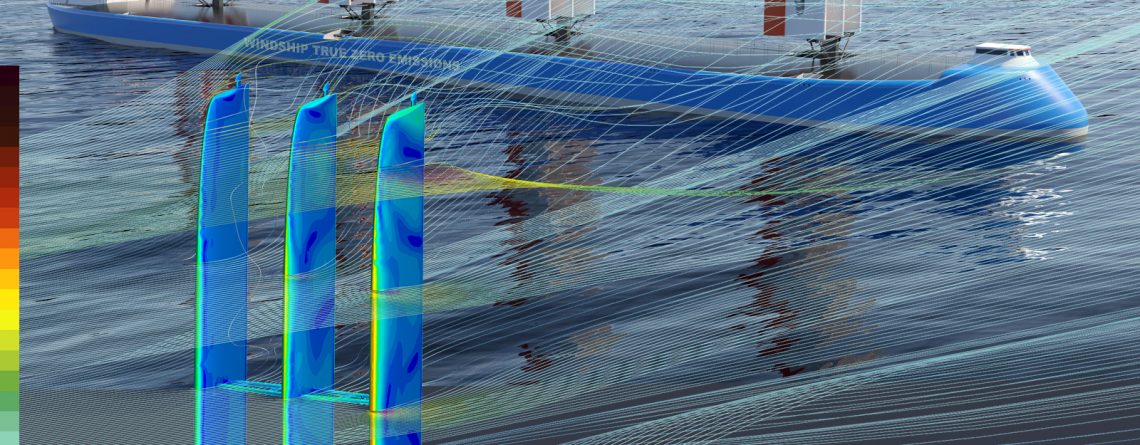

Leading expert knowledge and CFD analysis

Kate Porteous2022-09-20T12:29:58+00:00Due to their renowned experience and specialist technology, Cape Horn Engineering were commissioned to provide a holistic analysis of the Windship concept, Wind Propulsion Technology (WPT).

Dr.-Ing. Rodrigo Azcueta, Managing Director of Cape Horn Engineering is a leading CFD specialist, and marine engineering expert, recognised around the world for his work with shipbuilders, naval architects and yacht design teams.

He studied Naval Architecture and Marine Engineering in Buenos Aires and Hamburg, and following his graduation he continued working at the University of Hamburg on viscous free-surface flows and ship motions, for which he was conferred the degree of Doctor of Naval Engineering. His work as a research engineer at MTG Marinetechnik GmbH included projects for the German Ministry of Defence.

Later, as Head of hydrodynamic CFD for three America’s Cup Challenges, winning three consecutive Volvo Ocean Race Campaigns and as Head of CFD for a leading British America’s Cup Team, Azcueta has built his reputation upon a racing pedigree and winning formula over the last two decades.

He has since focused on building strong customer relations and has successfully expanded his business, extending the range of services, globally and across the broader maritime sector, with more recent ventures into the renewable energy sector. Investment in researching new technologies, dedicated to reducing shipping emissions and improving air pollution, is a strong commitment which has been made. Azcueta firmly believes the future will rely on sustainable energy sources and has a strong desire to contribute to this development and to improve the performance of renewable energy technologies.

“We have performed an extensive Computational Fluid Dynamic programme to improve the design and performance of the solid wings, as well as providing analytical evidence of potential savings.

Our CFD analysis gives understanding and also quantifies the link between the geometry of the wing and the driving force produced. Our studies provide accurate data of how the wings will perform in real conditions and how to improve the design. It is mainly based on the detailed analysis of the driving and side forces generated by each wing configuration. The other forces and moment generated by the airflow on the wings are also computed. By varying some shape and ratio parameters, such as the section’s profile, section’s thickness to chord ratio, main wing to flap chord ratio and wings separation, we can optimise the design to increase the performance.

A multitude of wing assembly shape configurations were analysed in varying wind conditions. In total, almost one thousand, high-fidelity CFD simulations were performed and analysed. The simulations were used to set up force models needed to describe the vessel’s hydrodynamic and aerodynamic behaviour. Operating conditions for the WPT devices were apparent wind angle and speed, wind shear and wind gradient (variation of wind speed and direction with height above the water surface), and angle of attack of the wings and its flaps.

These simulations were extremely valuable for improving the geometries of the wing assembly.

A significant gain in aerodynamic performance - a double digit percentage improvement was achieved by changing some parameters of the geometry.

Some selected simulation points were compared and validated with the wind tunnel testing, as well as with previous CFD analysis provided by Lloyds Register. Experts from the Wolfson Unit (University of Southampton) were also involved in the analysis of the CFD results. Extreme wind load cases were delivered to structural experts from Gurit for assuring optimum weight and safety of the structures.” comments Azcueta.

Windship and DNV unveil ‘first true zero-emissions’ design

Kate Porteous2021-02-17T10:51:31+00:00Tradewinds, the Global Shipping News Source, reported:

UK company claims new wind-powered system is the "Tesla of the seas". Windship Technology has revealed what it claims is the world's first truly zero-emissions ship system. The UK company has brought Norwegian classification society DNV on board to help develop a wind-powered design it refers to as the "Tesla of the seas".... "Per Marius Berrefjord, senior vice president at DNV, called the Windship team "experienced professionals". He said the project aims to help bring the entire shipping industry to "true zero" in terms of emissions. "Windship is supplying information in a fully transparent manner, and DNV will ensure a thorough verification process. We are looking forward to dive deeper into the very interesting technology presented by Windship," the DNV executive added. Windship is now looking to seal commercial partnerships with major shipowners, operators and investors, the UK company said. The Windship board includes former Concordia Maritime chief executive Lars Carlsson. The ex-tanker executive said: "The industry cannot sit back any longer. The clock is ticking and regulation will force a new approach for an industry that is traditionally hesitant to change." He added shipping is not fit for purpose for the future. Carlsson has been advocating wind power for a number of years. He said in 2019 that owners should be using all known fuel-saving methods, including wind propulsion, lower speeds, design and operational optimisation and biofuels derived from waste. And he called for new vessels to be built with anti-corrosion coated steel to give them a longer trading life of 50 years, a global fossil-fuel tax to encourage sustainable investment and the creation of a carbon exchange trading market.Read the full article from Tradewinds > Tradewinds subscribers, click here to find out more from Tradewinds >