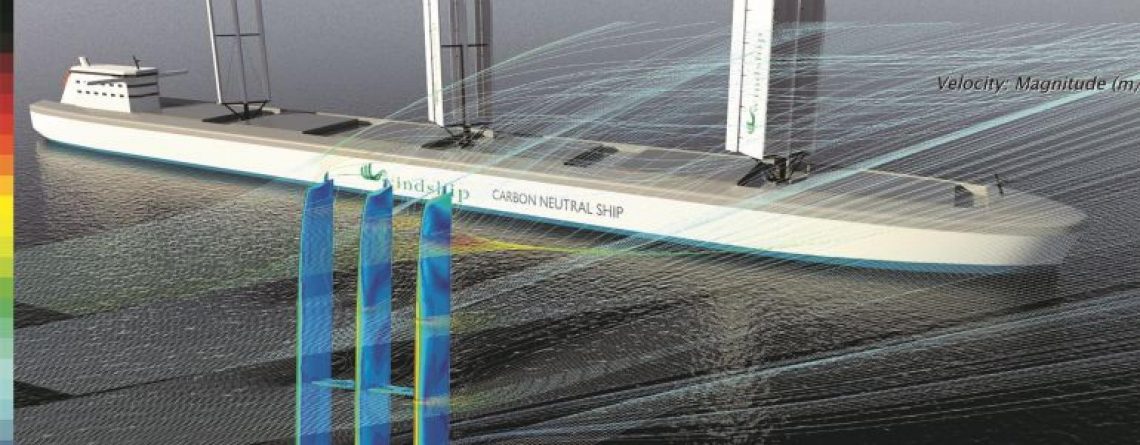

Use of fluid mechanics improves the efficiency of wind-assisted ships

UK-based Cape Horn Engineering has reported a two-digit percentage improvement in the aerodynamic performance of a vessel’s solid wing assembly via the use of Computational Fluid Dynamic (CFD) programme. The use of Wind Propulsion Technology (WPT) such as rigid wings, sails, kites, Magnus rotors on some vessels like bulk carriers and tankers have the potential of fuel savings and emission reductions around 10-30%.

Cape Horn Engineering said it is supporting one of its clients, Windship Technology, on a solid wing power concept that is being developed by a consortium of key players in the global shipping industry.

“We are extremely proud to be part of the team led by Windship Technology for this exciting project, running a CFD programme to further improve the design of the solid wings,” said Rodrigo Azcueta, managing director of Cape Horn Engineering.

“One of the key focuses of our project is to provide a clearer, unbiased and more detailed analysis of the new technologies available. The analytical evidence provided will give businesses a clearer understanding of the potential savings that can be realised with the implementation of the green propulsion systems. Without significant mitigating action it is projected that the global shipping industry could account for almost a fifth of carbon emissions by 2050,” Azcueta said.

Read the full Seatrade Maritime News article: here.